Equipment failures cost utilities millions annually – and each year, they are the root cause of nearly one third of customer interruptions. These outages not only leave utility customers without electricity, but also represent significant repair costs and risks to the employees performing these repairs. Until now, utilities have had limited ways of anticipating and mitigating these equipment-related issues, leaving electric utilities with few alternatives other than to wait for equipment to degrade to the point of failure. Even existing asset performance management (APM) approaches do not always predict equipment failures or help utilities best direct their resources. Several specific challenges include:

High cost. Unplanned repairs cost utilities millions of dollars in equipment, overtime, and other expenses annually, as well as revenue penalties in areas with performance-based regulations. Utilities need to vastly reduce these costs by shifting from unplanned to planned maintenance.

Blind spots in monitoring distribution equipment health. Current inspection technologies can’t detect equipment pre-failure radio frequency (RF) signatures at scale, and costly remote monitors and line post sensors can’t detect partial discharges indicating degraded components. Utilities can eliminate these blind spots with automated, continuous condition-based assessment.

Delayed discovery. Current techniques often miss issues until significant degradation or failures occur, resulting in high overtime costs, safety risks and longer power outages. With predictive insights, utilities can prevent these failures.

Difficulty prioritizing. Once degraded equipment is identified, utilities don’t always endeavor to determine which equipment to prioritize for repair. To maximize effectiveness, utilities need a better way to prioritize issue corrections.

Analytical limitations. With limited access to data science expertise and sparse condition-based monitoring data, utilities have limited insights into infrastructure integrity. Utilities need timely insights at their fingertips.

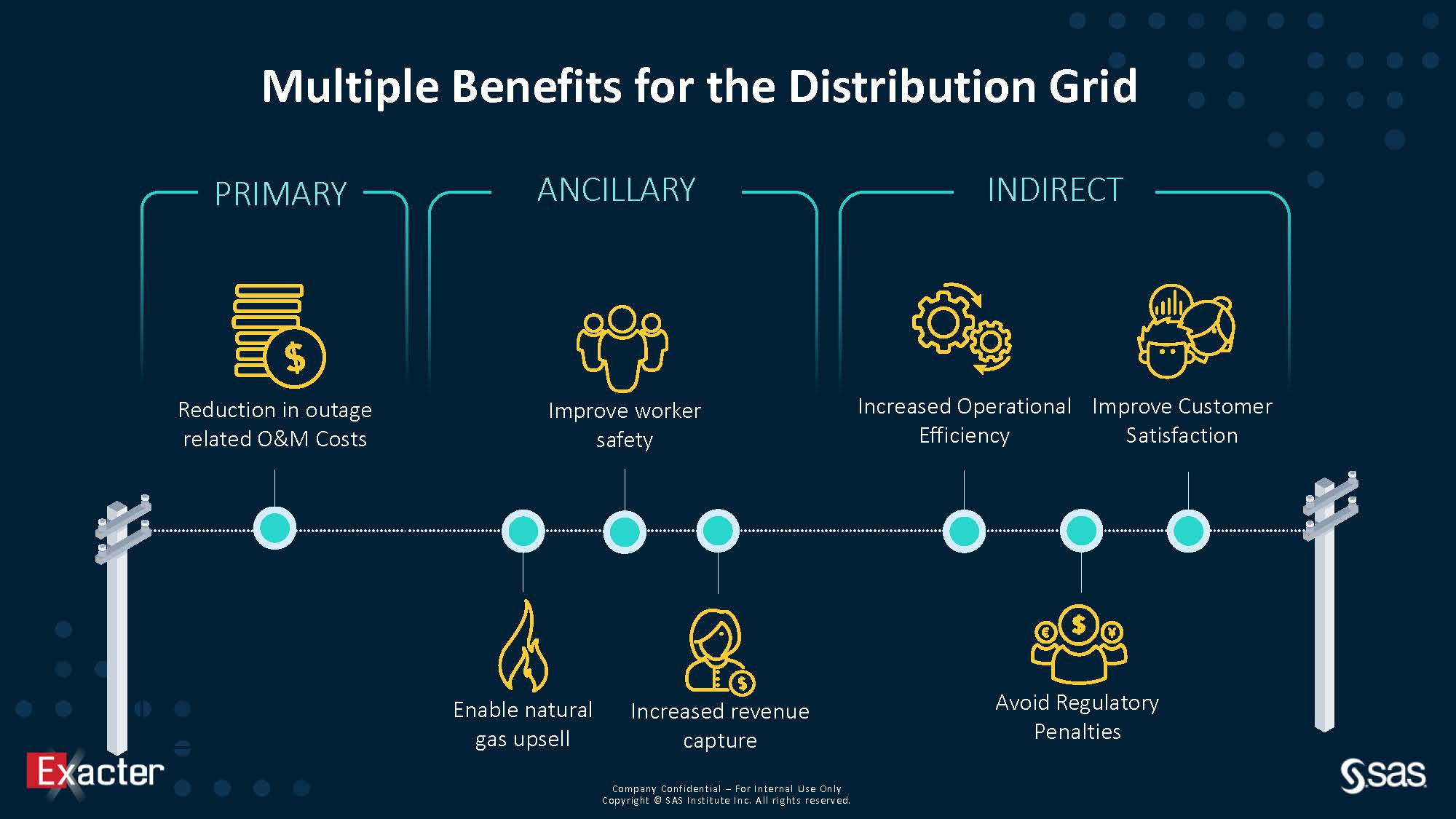

But with new capabilities, utilities can address these challenges head on, eliminating equipment failure so that the grid is more reliable, workers are safer, costs are lower, and customers are satisfied with the service they receive.

SAS recommends that utilities consider an approach that enables:

- Accurate, reliable, and low-cost detection of degraded distribution equipment by leveraging mobile sensor networks.

- Data management, data quality and data analytics to generate insights.

- Condition-based repair and maintenance that can preempt unplanned loss of service, collateral damage to equipment and added safety risk to workers.

- Integration with existing work order systems to minimize disruption to existing processes.

The result? Shorter and less frequent customer interruptions, reduced restoration costs, safer work environments and improved customer satisfaction.

If you’d like to learn more about how utilities can achieve next-level reliability and service levels by complementing existing APM approaches with edge-computing sensing technology and advanced analytics focused on RF emissions from equipment, contact jane.howell@sas.com.

About SAS in IoT

SAS empowers organizations to create and sustain business value from diverse IoT data and initiatives, whether that data is at the edge, in the cloud, or anywhere in between. Our robust, scalable, and open edge-to-cloud analytics platform delivers deep expertise in advanced analytics – including AI, machine learning, deep learning, and streaming analytics – to help customers reduce risk and boost business performance. Learn more about our industry and technology solutions at www.sas.com/iotsolutions

Jane Howell, Principal, IoT, SAS

Mark Konya, Advisory Industry Consultant, Energy, SAS

Craig Foster, Principal, IoT, SAS