Digital transformation has revolutionized the utility industry in recent years, and the integration of drone technology and artificial intelligence (AI) is no exception. Utilities are beginning to leverage the power of drone inspection and AI to improve grid analytics and increase the efficiency and reliability of their operations. By utilizing drone technology and AI algorithms, utilities can gather and analyze data on grid infrastructure and vegetation growth to proactively identify potential issues and reduce downtime.

Utilities are experiencing several trends that are the driving forces behind the push to digitally transform asset inspections and improve network reliability and resiliency. These trends include:

- Comprehensive asset visibility: AI and data will be at the center of this transformation as companies transition from just tracking defects to having a comprehensive view of overall grid asset health.

- Improved inspection frequency and accuracy: Utilities wish to increase the frequency and number of inspections to yield higher quality results without straining maintenance team resources or increasing costs. The goal is to identify issues before they impact consumers—improving customer satisfaction and raising System Average Interruption Frequency Index (SAIFI).

- Capture the knowledge and automate: Knowledge and expertise are retiring, with up to 40% of current maintenance workers eligible for retirement by 2030. This is a driving catalyst prompting utilities to identify new methods and techniques before maintenance resource limitations begin impacting service delivery and reliability.

- Culture of safety: Conducting asset inspections manually requires work at elevation and near high voltage lines. Utilizing drones and automated inspection technologies can significantly reduce dangerous work environment exposure.

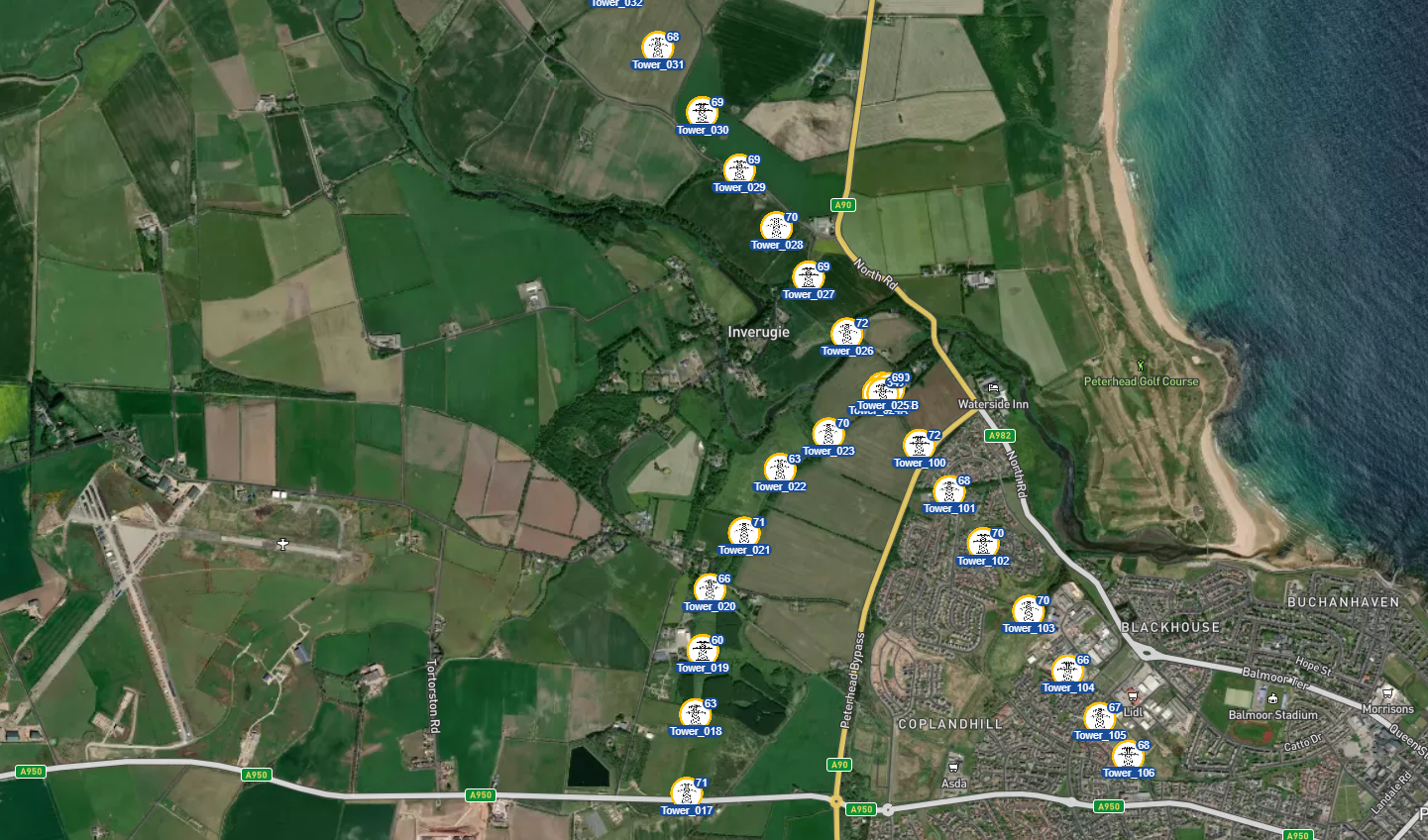

One of the most significant benefits of using drones and AI for grid analytics is the ability to conduct remote inspections of grid infrastructure. Drones equipped with high-resolution cameras and sensors can capture data on power lines, transmission towers and other critical infrastructure. AI algorithms can then analyze this data to detect defects, wear and tear, and other issues that may require attention, thus enabling utilities to identify and address potential problems quickly.

By using drone inspection and AI, utilities can reduce the cost and time associated with manual inspections, improving the speed and accuracy of their maintenance and repair operations. This technology also can improve worker safety by reducing the need for technicians to climb high transmission towers or work in hazardous conditions.

Getting started with AI-powered grid analytics begins with effective data management because data is the foundation of all digital transformation initiatives. The steps to implementing an inspection automation program with AI include:

- Establish Unified Data Management: Once visual data is captured, a single source of truth is required where image data can be centrally managed.

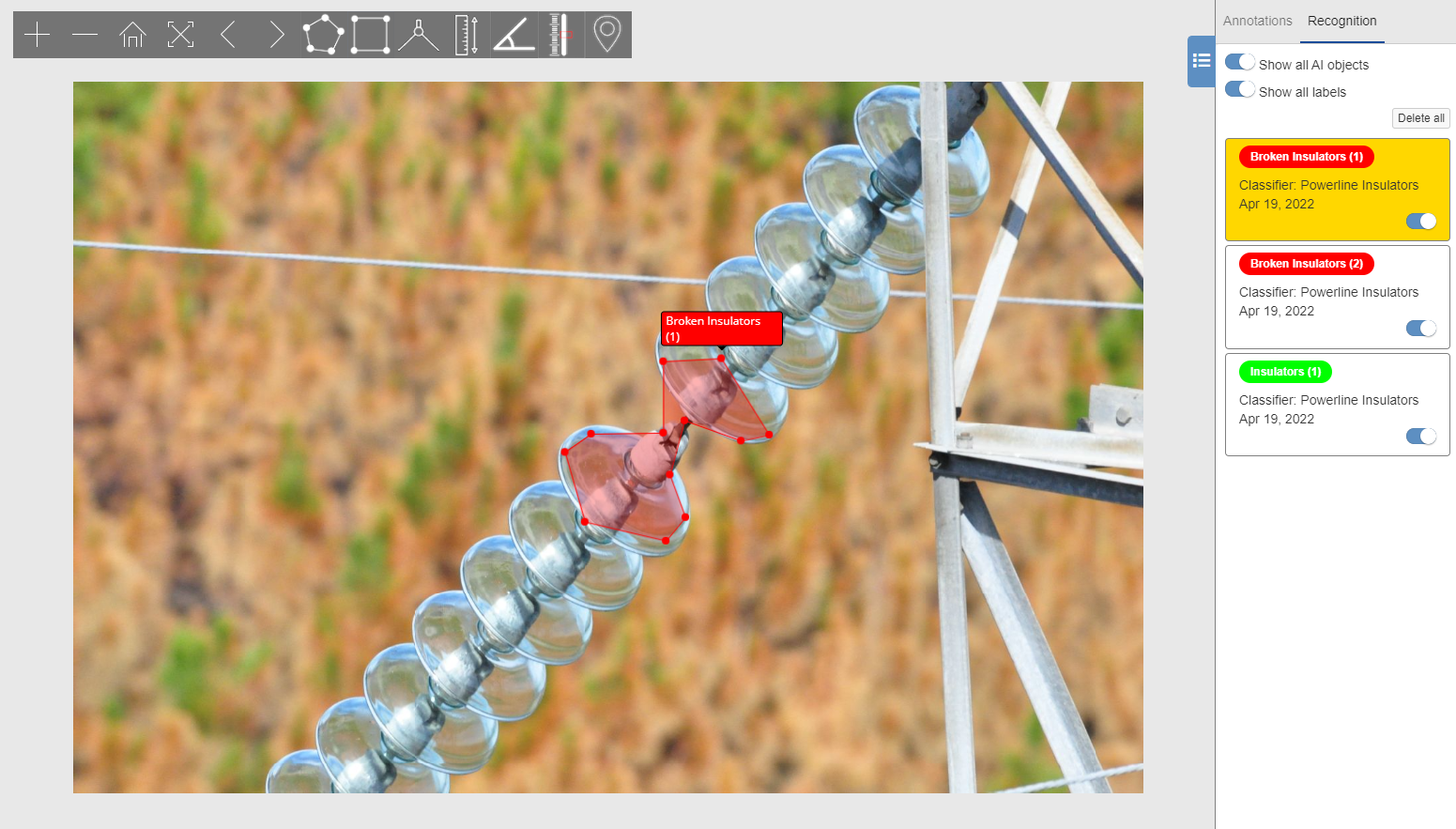

- Image labeling Process: Identification of the asset (insulator) and the defect (crack) is the first step in AI Classifier development.

- AI Creation: Create AI models from the data in Step 2 using labeled datasets or use existing data sets from the Electric Power Research Institute (EPRI) to create AI.

- Operationalize: Deploy the developed AI Classifier to process new images and automate the defect detection process. Follow-up action may include enterprise system integration to automate ticketing and dispatch, work order routing, inventory management, and personnel scheduling.

The digital transformation of grid analytics is still in its early stages, but many large utilities have started programs to gain understanding of key applications for later expansion, and the early results are encouraging. Utilities that have implemented inspection automation programs with drone inspection and AI have experienced several tangible benefits which improve operational efficiency:

- Increased inspection capacity: +280% increase in inspection capacity utilizing the same resources.

- Improved inspection accuracy: Defect detection increased by +37%, dramatically increasing the number of failure conditions (with impacts on grid reliability) detected.

- Higher job satisfaction: Maintenance inspectors spend their time verifying and classifying identified issues flagged by AI, reducing fatigue caused by repetitive image analysis and improving job satisfaction.

In summary, digitally transforming your grid analytics program by using drone inspection and AI analysis offers several benefits to utilities. These include increased efficiency, improved safety, enhanced asset management, early detection of issues and cost savings. Drones can cover a large area quickly and efficiently, while AI algorithms can detect anomalies and predict equipment failures, allowing utilities to address issues before they become major problems.

By optimizing operations and reducing downtime, utilities can improve their reliability while saving money in the long run. If you’re interested in learning more about how utilities are digitally transforming their asset inspection programs, you can read our full article here. For a free AI consultation or demonstration of the capabilities of the Optelos visual data management platform, contact us at hello@optelos.com.