The utility sector is facing unprecedented operational challenges. As critical infrastructure ages and demand grows, maintaining reliable services while keeping costs and risks in check has become increasingly difficult. Traditionally, utilities have relied on time-based maintenance—an approach that schedules inspections and repairs at set intervals, often based on manufacturer recommendations. However, this method can lead to over-maintenance, resulting in wasted resources, or under-maintenance, leading to costly and dangerous equipment failures.

To address these issues, many utilities are turning toward condition-based maintenance (CBM), a proactive strategy where repairs and replacements are carried out based on the actual condition of assets, informed by real-time data. Emerging technologies, particularly drone-based inspection systems and autonomous monitoring solutions, are now playing a pivotal role in facilitating this transition.

The Problem: Challenges in Asset Management and Maintenance

Utility companies operate in a highly complex environment where balancing cost, risk, and performance is a constant challenge. The aging infrastructure across the industry requires more frequent monitoring, but manual inspections are time-consuming, labor-intensive, and often risky, especially when dealing with high-voltage lines or hard-to-reach areas. Moreover, the aging workforce compounds this issue, as much of the expertise needed to perform these tasks resides with personnel nearing retirement, with limited plans in place to transfer this knowledge to the next generation.

Utilities also face external pressures from stakeholders and regulators. Customers expect reliable and affordable services, while regulatory bodies demand strict compliance with safety and reliability standards. These pressures are exacerbated by the increasing frequency of extreme weather events, which pose immediate threats to grid reliability and require swift responses.

In this context, utility companies need to move away from inefficient time-based maintenance strategies and embrace data-driven approaches that enable proactive, just-in-time interventions based on the actual condition of their assets.

Technology Solutions: Drones, Docks, and Data Integration

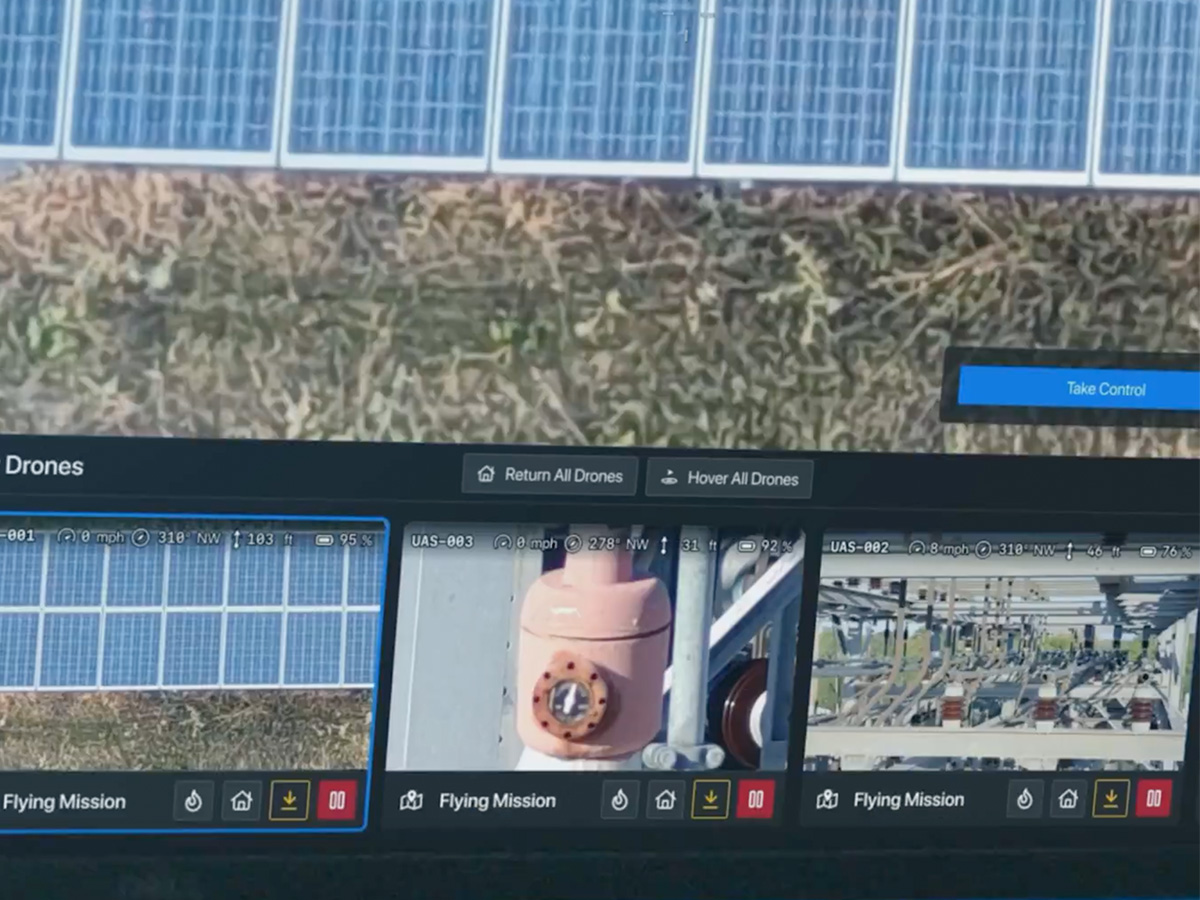

Drone technology and autonomous inspection systems have emerged as essential tools in the transition to condition-based maintenance. These technologies enable utility companies to perform real-time asset monitoring, dramatically improving the efficiency, safety, and reliability of their maintenance programs. Below, we explore the core components of this technology ecosystem and how it addresses the key challenges in utility operations.

Drone-Based Inspections: Comprehensive Asset Monitoring

Drones equipped with high-resolution cameras and thermal imaging sensors offer a more comprehensive view of utility infrastructure, allowing companies to monitor critical assets such as transmission lines, substations, and transformers. Drones can cover vast areas more quickly and efficiently than ground-based teams, providing a level of detail that manual inspections often miss. Research shows that drone inspections can reduce inspection times by as much as 70%, particularly in difficult-to-access locations.

By employing machine learning algorithms, drones can analyze images and detect anomalies such as corrosion, overheating, or structural wear. This capability allows utility companies to identify early warning signs of equipment failure before they escalate into more significant, costly problems. Additionally, drone systems can integrate with utility asset management platforms, providing operators with an uninterrupted flow of data that can be analyzed and archived for audit and compliance purposes.

Dock-Based Automation: Autonomous, On-Demand Monitoring

Dock-based drone systems, which enable autonomous flight operations, represent a significant step forward in reducing the operational burden on utilities. Docks serve as permanent bases for drones, allowing them to be deployed on pre-programmed missions or in response to real-time triggers such as severe weather or security incidents. By automating routine inspections, utilities can minimize the need for manual deployment of field personnel, improving both safety and efficiency.

A case study from a U.S. utility demonstrates how dock-based systems can significantly reduce outage times. Following a severe storm, the utility was able to deploy drones from dock systems immediately after the weather cleared, assessing damage and identifying priority repairs within minutes. This approach saved valuable time and allowed repair crews to be dispatched with specific instructions, reducing downtime by 30% compared to traditional response methods.

Real-Time Data Integration: Turning Insights into Action

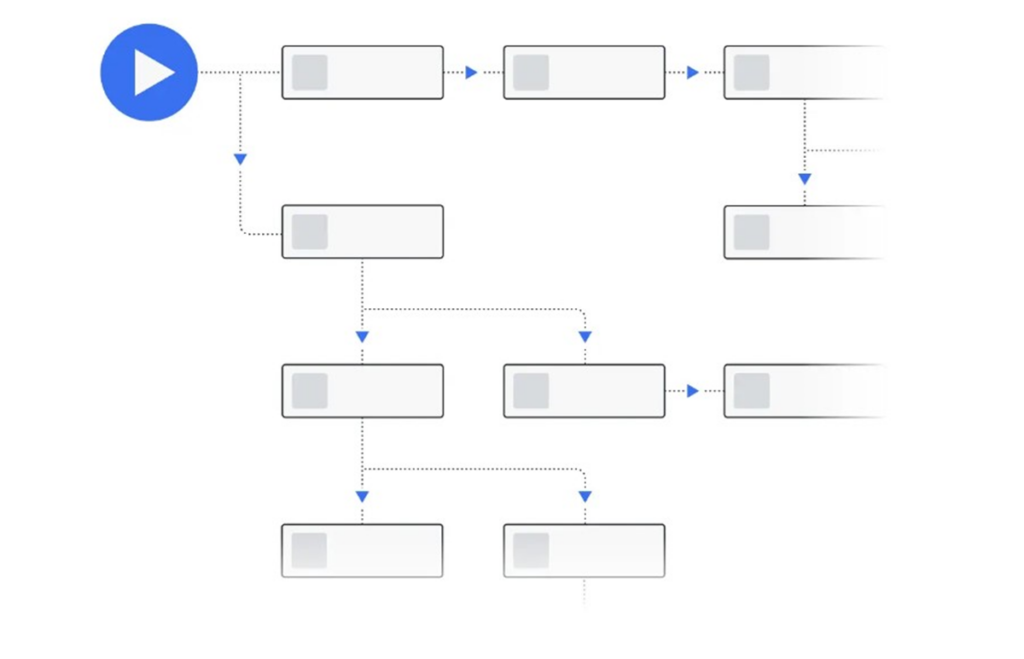

One of the most transformative aspects of drone and dock systems is their ability to integrate real-time data into broader asset management platforms. These systems provide seamless connectivity to cloud-based analytics platforms, where data from inspections is processed and analyzed. By using advanced analytics and artificial intelligence, utilities can develop a continuous understanding of their asset health, enabling them to make more informed decisions about maintenance and repairs.

For example, predictive maintenance models based on data gathered from drones can calculate the remaining lifespan of critical components, helping utilities prioritize maintenance activities based on actual need rather than a preset schedule. This approach significantly reduces unnecessary maintenance actions and extends the life of expensive infrastructure. Furthermore, integrating this data with existing systems such as customer interactions, asset management, and geographical information, etc. ensures that insights gained from drone inspections can be directly translated into actionable work orders, improving the speed and accuracy of maintenance operations.

Methodology and Best Practices: How to Implement Condition-Based Maintenance

Transitioning to a condition-based maintenance strategy requires a structured approach that integrates both technology and process improvements. Below are best practices for utilities looking to implement CBM using drones and autonomous inspection systems:

1. Data Collection and Analysis: Develop a methodology for capturing high-quality, consistent data using drone-based inspections. Establish key performance indicators (KPIs) that track the health of critical assets and enable predictive maintenance models.

2. Automation of Routine Inspections: Implement dock-based systems to automate routine asset monitoring, reducing manual intervention and improving operational efficiency.

3. Real-Time Analytics and Decision Support: Integrate drone data with existing utility platforms and use advanced analytics to process inspection data in real-time. Ensure that findings are directly integrated into work order management systems to streamline repairs and reduce downtime.

4. Workforce Training and Knowledge Transfer: Address the aging workforce by ensuring that new systems are easy to use and can be operated with minimal training. Document best practices and workflows to facilitate knowledge transfer between retiring staff and new hires.

Conclusion: The Future of Utility Maintenance

As utilities face mounting pressure to deliver reliable, cost-effective services, transitioning to condition-based maintenance is no longer a question of if but when. Drone technology, dock-based automation, and advanced data analytics offer a proven path toward smarter, more proactive asset management. By adopting these innovations, utility companies can reduce the frequency and severity of outages, optimize their maintenance budgets, and enhance overall system reliability.

About the Author

Christina Park joined Skydio as the Sr. Director of Energy Strategy after 15+ years at the New York Power Authority. Her experience in the utility industry spanned Engineering from design to commissioning in Power Generation before a shift to Strategic Operations and Asset Management. As Sr. Director of Asset Intelligence Solutions, she led the comprehensive effort to operationalize technology across the enterprise. By standing up the Reliability Centered Maintenance program and identifying the gaps for Technical Enablement to bring solutions to scale, her department tested and incorporated robotics, sensors, and data analytics to connect problems to solutions. She is a licensed Professional Engineer with a BS and MS in Mechanical Engineering from MIT.

is a sponsor of

UA Week 2024 is brought to you by Utility Analytics Institute and is produced by Endeavor Business Media