In Chicago, Illinois, Oracle has built a state-of-the-art facility that brings together utility customers, technology partners, and subject matter experts to collaborate and accelerate innovation. It’s known as the Oracle Industries Innovation Lab. One of many current experiences involves using image recognition technology and autonomous robots to execute asset inspection activities within the utility space.

Asset inspection represents a significant cost for utility companies. It is highly manpower-intensive, prone to human mistakes, and generally lacks integration with utility IT infrastructures, which prevents automation and makes cost reduction difficult. Typically, inspections are performed manually, following a strict seasonal schedule—accompanied by considerable safety, logistic, and budgetary considerations.

This project challenged Oracle to find ways of optimizing asset inspections without direct contact and to minimize unnecessary preemptive maintenance programs to reduce expenses. Implementing this experience in the Innovation Lab revealed challenges that may not have otherwise been discovered.

The Lab Arrangement and Configuration

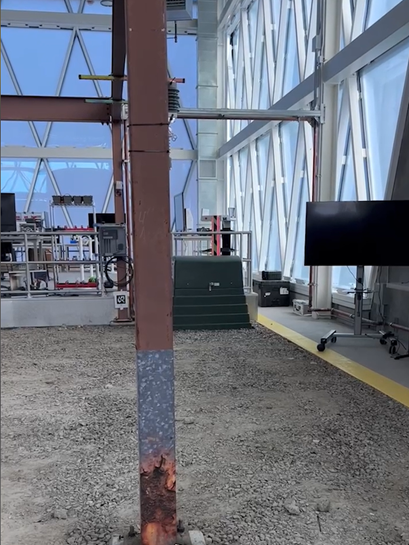

Replica utility poles within the lab were utilized for this project; future plans include installing genuine utility poles, generously donated by Exelon. The pole in the background is considered to be “in good condition” with its galvanized steel and cross-arm still holding up well. However, the pole in the foreground has deteriorated significantly, displaying notable rust on the lower portion as well as a cracked cross-arm.

Data capture with autonomous drone, Skydio

Data Capture with Autonomous Drone, Skydio

Operating remotely, Skydio drone flights were executed in the Chicago-based Innovation Lab to perform the infrastructure inspection.

The collaboration also used Oracle’s AI Vision Service and a custom vision model, which was trained to identify rust damage by taking and evaluating hundreds of photos of both healthy and unhealthy poles.

Once the drone captures the footage, it is transmitted to Oracle’s AI Vision Services, where the AI (artificial intelligence) model comes into play to identify any sign of rust or decay on the utility poles. The results are then fed into Oracle’s Work and Asset Management software, classifying each pole as “in good condition” or “rusty”. Subsequently, using Oracle’s Field Services, specialized technicians can further examine the poles and carry out the necessary maintenance work.

The Outcome

By harnessing the capabilities of AI and autonomous systems, flights were triggered remotely and successfully acquired inspection results from the lab. In addition to data science, integrating the outcomes of AI with asset and field service applications completed the analytics process, resulting in a level of automation that offers cost savings and business benefits for utilities. The entire workflow is showcased in this video. By adopting this method, field teams can prioritize cases that require urgent attention and triage the remaining ones, resulting in a level of efficiency that was not previously attainable for such a labor-intensive task.

Whether the drones and autonomous robots are fully automated or operated by field staff, this asset inspection process presents a reliable, scalable, and repeatable platform that resolves various issues and ensures greater precision and effectiveness.

Oracle industry-focused teams

We are merely at the outset!

Oracle isn’t only leveraging ground-breaking technologies; in addition, industry-focused teams are designing flexible solutions that intend to revolutionize the energy sector. The vision unlocks a connected tomorrow where grid planning is more intelligent and resilient, utilities can inform and contribute to electric vehicle network planning, and customers can be offered a comprehensive overview of their energy and water consumption across all suppliers.

Oracle has spent the past 20 years building the field of AI from the ground up — helping democratize access to AI and machine learning. In order to enable the democratization of data and simplify data inquiries from external organizations, Oracle is developing the Energy and Water Data Exchange platform. This platform offers tools that will bring about a revolutionary change in the method utilities use to access, process, and analyze data. This new Oracle Data Exchange Platform is purpose-built for the energy industry. (Experience a demo here.)

Analytics will be surfaced across all datasets. Cross-platform insights will be embedded within products and available throughout the utility organization. Utility data science teams can use this data to uncover their own insights, or benefit from pre-trained Oracle insights.

We invite you to participate in co-innovating at the Oracle Industries Innovation Lab. Together, we have the potential to transform possibilities into realities and unlock a connected tomorrow.

Jason Kriendler, Director Product Management, Enterprise Analytics, Oracle Energy and Water

Jason Duncan-Wilson, Senior Director, Product Incubator, Oracle Energy and Water